CNC Machining Centers: Revolutionizing Manufacturing Precision and Efficiency

2024-07-24

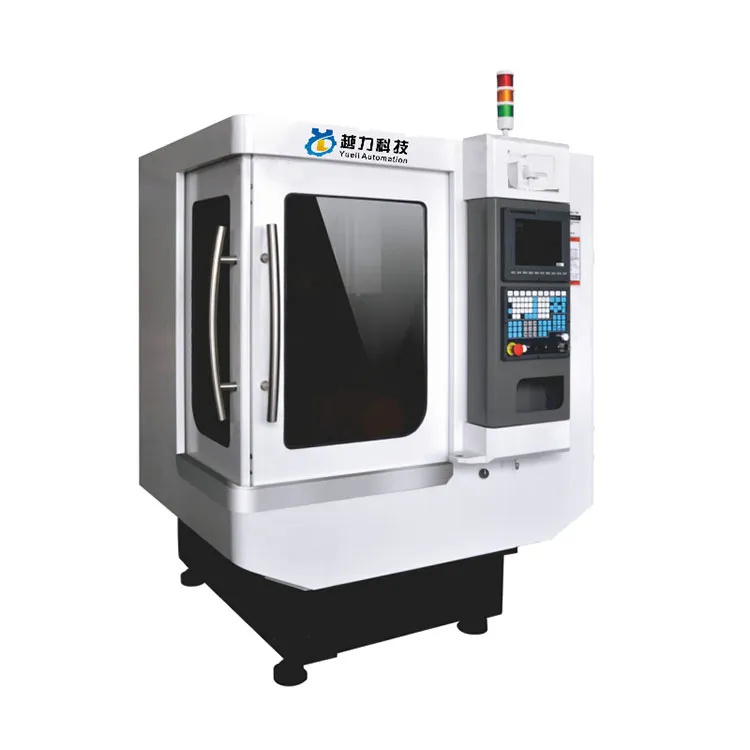

The manufacturing industry has undergone a significant transformation with the advent of Computer Numerical Control (CNC) machining centers. These advanced machines have redefined precision, efficiency, and versatility in producing complex parts and components. In this blog, we will explore what CNC machining centers are, their benefits, key features, and their impact on modern manufacturing.

What is a CNC Machining Center?

A CNC machining center is an automated machine tool that uses computer-controlled processes to precisely remove material from a workpiece to create a desired shape. These centers combine multiple machining operations such as milling, drilling, and tapping in a single setup, increasing productivity and reducing the need for multiple machines.

Benefits of CNC Machining Centers

1. Unmatched Precision: CNC machining centers can achieve incredibly tight tolerances, ensuring parts are produced with consistent accuracy. This level of precision is crucial for industries such as aerospace, medical, and automotive, where even the smallest deviation can impact performance and safety.

2. Increased Efficiency: By automating the machining process, CNC machining centers significantly reduce production times. They can operate continuously with minimal human intervention, allowing for high-volume production runs with consistent quality.

3. Versatility: CNC machining centers can handle a wide range of materials, including metals, plastics, and composites. Their ability to perform multiple operations in one setup makes them versatile and suitable for various applications.

4. Cost Savings: The efficiency and precision of CNC machining centers lead to reduced material waste and lower labor costs. Additionally, their ability to produce complex parts in a single setup reduces the need for multiple machines and processes, further cutting production costs.

Key Features of CNC Machining Centers

1. Multi-Axis Capability: Most CNC machining centers come with multi-axis capabilities, typically ranging from 3 to 5 axes. This allows for complex machining operations and the production of intricate parts with minimal setups.

2. Automatic Tool Changer (ATC): CNC machining centers are equipped with an automatic tool changer that can hold multiple tools and switch between them during the machining process. This feature enhances efficiency by reducing downtime for manual tool changes.

3. High-Speed Spindles: The spindles in CNC machining centers can operate at high speeds, enabling fast material removal rates and improved surface finishes. High-speed machining is essential for producing high-precision parts quickly.

4. Advanced Control Systems: Modern CNC machining centers use sophisticated control systems that allow for precise control over the machining process. These systems can interpret complex CAD/CAM files, enabling the production of intricate designs with ease.

5. Robust Construction: CNC machining centers are built to withstand the rigors of heavy-duty machining. They feature rigid structures and advanced damping systems to minimize vibrations and ensure stability during operation.

Impact on Modern Manufacturing

1. Improved Product Quality: The precision and consistency offered by CNC machining centers result in higher-quality products with fewer defects. This is particularly important in industries where reliability and performance are critical.

2. Enhanced Innovation: CNC machining centers enable manufacturers to produce complex and innovative designs that were previously impossible or impractical with traditional machining methods. This capability fosters innovation and allows companies to stay competitive in the market.

3. Reduced Lead Times: The efficiency of CNC machining centers reduces lead times for product development and production. This allows manufacturers to respond quickly to market demands and customer requirements.

4. Sustainability: By reducing material waste and energy consumption, CNC machining centers contribute to more sustainable manufacturing practices. This is increasingly important as industries strive to minimize their environmental impact.

Conclusion

CNC machining centers have revolutionized the manufacturing industry by providing unmatched precision, efficiency, and versatility. Their ability to produce complex parts with consistent quality has made them indispensable in various industries. As technology continues to advance, CNC machining centers will play an even more critical role in shaping the future of manufacturing. Whether you are a manufacturer looking to improve your production processes or a business seeking high-quality components, CNC machining centers offer the capabilities and benefits to meet your needs.