How Can Modern Reduction Rolling Mills Help Manufacturers Balance Precision, Output, and Cost?

2026-01-05

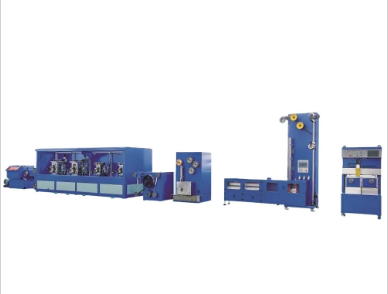

When I first started evaluating rolling solutions for long steel production, I quickly realized that not all mills are built with the same philosophy. In recent years, as I worked more closely with Youzha, I began to see how thoughtfully engineered Reduction Rolling Mills could quietly solve many of the problems manufacturers struggle with every day—without forcing drastic changes to existing production lines. What impressed me most was not just the equipment itself, but how naturally it fit into real-world rolling environments where consistency, efficiency, and control matter more than flashy specifications.

Why Do Manufacturers Still Struggle With Dimensional Accuracy After Rough Rolling?

In my experience, dimensional deviation is one of the most common complaints in bar and wire rod production. Even after a well-designed roughing mill, slight inconsistencies in size, ovality, or surface finish can carry downstream and amplify during finishing.

This is exactly where Reduction Rolling Mills prove their value. By applying controlled micro-reductions after rough rolling, these mills help stabilize material geometry before it reaches the finishing stands. Instead of correcting errors later—often at higher cost—the process focuses on early precision.

- Improved size tolerance without aggressive deformation

- Reduced internal stress in the rolled material

- More predictable performance in finishing mills

How Can Reduction Rolling Mills Improve Product Quality Without Slowing Production?

A common concern I hear is whether adding another rolling stage will compromise throughput. From what I have seen, the opposite is often true. Properly configured Reduction Rolling Mills optimize deformation efficiency rather than increase rolling time.

By focusing on smaller, precise reductions, the rolling force is distributed more evenly. This results in smoother material flow, fewer defects, and less wear on downstream equipment.

| Production Aspect | Without Reduction Rolling | With Reduction Rolling Mills |

|---|---|---|

| Dimensional consistency | Variable across batches | Stable and repeatable |

| Surface quality | Higher risk of minor defects | Smoother finish |

| Downstream load | Higher correction demand | Reduced finishing stress |

What Makes Reduction Rolling Mills a Practical Upgrade for Existing Lines?

One reason I often recommend Reduction Rolling Mills is their adaptability. Unlike major mill overhauls, these systems can usually be integrated into existing layouts with minimal disruption.

From my perspective, this makes them particularly attractive for plants looking to upgrade quality without shutting down production for extended periods.

- Compact design suitable for limited plant space

- Compatibility with multiple steel grades

- Flexible adjustment for different product sizes

Working with Youzha, I noticed a strong emphasis on practical engineering—solutions designed for operators, not just idealized lab conditions. That mindset is often reflected in stable operation and easier maintenance over time.

How Do Reduction Rolling Mills Help Control Operating Costs Long Term?

Cost control is rarely about one dramatic saving; it is about many small efficiencies adding up. In daily operation, Reduction Rolling Mills contribute to lower overall costs in ways that are not always obvious at first glance.

| Cost Factor | Operational Impact |

|---|---|

| Roll wear | Extended service life due to smoother load distribution |

| Energy consumption | Lower peak loads during finishing stages |

| Scrap rate | Reduced rework from dimensional defects |

Over time, these incremental improvements can significantly improve overall plant profitability while maintaining stable output levels.

Are Reduction Rolling Mills Suitable for Diverse Market Demands?

From construction steel to higher-precision industrial applications, market expectations continue to rise. I have seen how Reduction Rolling Mills help producers respond to these demands with greater flexibility.

By fine-tuning final dimensions and improving consistency, manufacturers can confidently supply markets that require tighter tolerances without redesigning their entire rolling process.

Looking for a Reliable Way to Upgrade Rolling Performance Without Overcomplicating Your Line?

If you are evaluating options to improve product quality, stabilize output, and manage long-term operating costs, Reduction Rolling Mills deserve serious consideration. Based on my experience, solutions developed with practical production realities in mind—like those from Youzha—offer a balanced path forward.

If you want to explore how a tailored rolling solution could fit into your existing line, I encourage you to contact us and start a direct conversation. Share your production goals, challenges, and expectations, and let’s see how the right rolling approach can support your next stage of growth.