How Metal Laser Cutting Machines Are Revolutionizing Manufacturing

2024-08-16

Introduction

In the world of manufacturing, precision, speed, and efficiency are paramount. The advent of metal laser cutting machines has revolutionized the industry, providing a tool that offers unmatched accuracy and versatility. This blog explores how metal laser cutting machines have transformed the manufacturing landscape, their benefits, and the impact they have on various industries.

The Evolution of Metal Cutting

Traditional metal cutting methods, such as mechanical sawing, punching, and milling, have long been used in manufacturing. However, these methods often come with limitations, including slower processing times, lower precision, and the potential for material wastage. The introduction of laser technology into metal cutting has addressed these challenges, offering a more efficient and precise alternative.

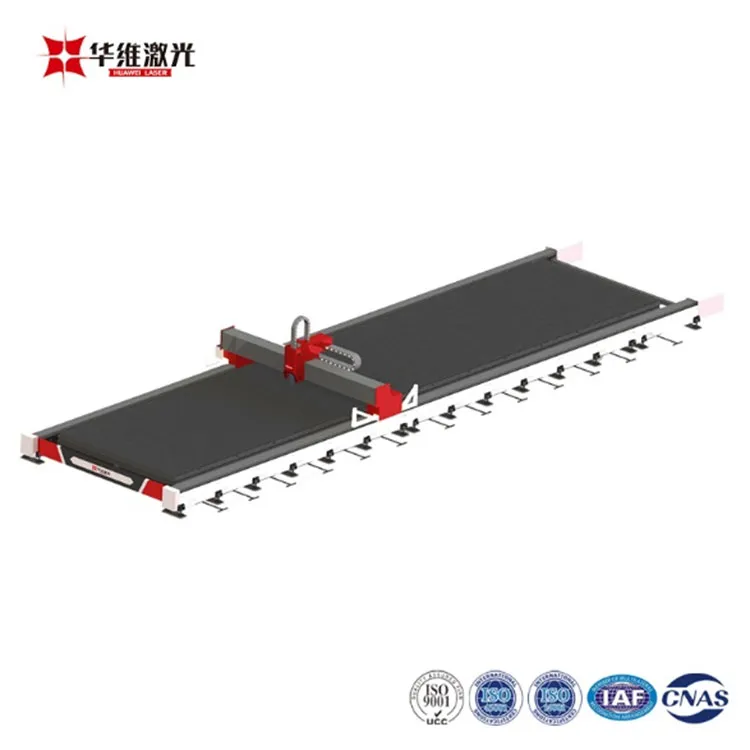

What Is Metal Laser Cutting?

Metal laser cutting involves the use of a high-powered laser beam to cut through metal materials. The laser focuses a concentrated beam of light onto the metal, heating it to the point of melting or vaporization. The precision of the laser allows for intricate cuts with minimal waste and no direct contact with the material, reducing the risk of contamination or damage.

Key Benefits of Metal Laser Cutting Machines

- Precision and Accuracy: Metal laser cutting machines offer unmatched precision, allowing manufacturers to create intricate designs and complex geometries with ease. The accuracy of laser cutting is often within microns, making it ideal for industries that require high levels of detail.

- Speed and Efficiency: Laser cutting is significantly faster than traditional methods, allowing for quicker production times. This speed does not compromise accuracy, making it possible to produce large quantities of parts in a short amount of time.

- Versatility: Laser cutting machines can handle a wide range of materials, including steel, aluminum, copper, and titanium. This versatility makes them suitable for various industries, from automotive and aerospace to electronics and medical devices.

- Reduced Material Waste: The precision of laser cutting reduces the amount of material wasted during the cutting process. This not only saves costs but also contributes to more sustainable manufacturing practices.

- Minimal Maintenance: Unlike mechanical cutting tools that require frequent sharpening and replacement, laser cutting machines have minimal wear and tear. This leads to lower maintenance costs and longer machine life.

Applications Across Industries

The impact of metal laser cutting machines extends across numerous industries:

- Automotive: In the automotive industry, laser cutting is used to create precise components, such as engine parts, exhaust systems, and body panels. The ability to produce complex shapes with high accuracy is crucial in this industry.

- Aerospace: The aerospace industry relies on laser cutting for creating lightweight yet strong components. The precision of laser cutting is essential for ensuring the safety and performance of aircraft.

- Electronics: Laser cutting is used to manufacture intricate parts for electronic devices, such as circuit boards and enclosures. The accuracy of laser cutting is critical in producing components that meet tight tolerances.

- Medical Devices: In the medical field, laser cutting is used to create surgical instruments, implants, and other medical devices that require high precision and biocompatibility.

Conclusion

Metal laser cutting machines have revolutionized the manufacturing industry by offering a precise, efficient, and versatile solution for cutting metal materials. Their ability to produce intricate designs with minimal waste has made them an invaluable tool across various industries. As technology continues to advance, the capabilities of metal laser cutting machines are likely to expand, further transforming the manufacturing landscape.