What are the components of Heavy Duty Connector?

2024-01-09

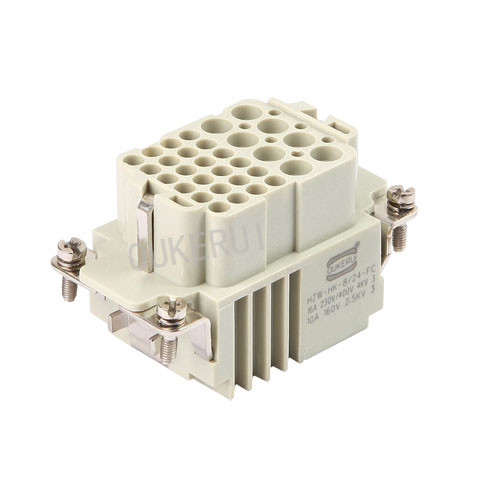

Heavy-duty connectors, also known as industrial connectors, are robust and reliable electrical connectors designed for demanding industrial applications. They typically consist of several components that allow for secure and efficient electrical connections in harsh environments. The specific components of a heavy-duty connector can vary based on the manufacturer and the connector's design, but the following are common components found in these connectors:

1. Housing/Enclosure: The main body of the heavy-duty connector that holds and protects the internal components. It is usually made of sturdy materials like metal (aluminum, zinc, stainless steel) or high-grade plastics, providing mechanical protection and resistance to environmental factors (such as moisture, dust, chemicals, and impact).

2. Inserts/Modules: These are removable components inside the housing that hold and organize the electrical contacts or terminals. Inserts can be configured with different numbers and types of contacts (pins, sockets, or mixed configurations) to accommodate various wiring requirements. They facilitate the connection and disconnection of wires or cables.

3. Contacts/Terminals: Electrical contacts or terminals are the components that establish the electrical connection between mating connectors. They come in different configurations, such as crimp contacts, solder contacts, or screw terminals, and they are made of materials suitable for high conductivity and resistance to corrosion.

4. Locking Mechanism: Heavy-duty connectors often feature locking mechanisms or locking levers to ensure secure mating and locking of connector halves, preventing accidental disconnection due to vibrations or movement.

5. Gaskets/Seals: To provide ingress protection against water, dust, and other environmental elements, heavy-duty connectors may include gaskets or seals at the mating interface. These seals help maintain the connector's IP (Ingress Protection) rating.

6. Coding Elements: Some connectors have coding elements or keys that ensure proper mating by preventing incorrect connections or mismating with connectors of different configurations.

7. Mounting Accessories: Mounting accessories, such as brackets, screws, or mounting rails, may be included to facilitate the installation of the connector onto machinery, control panels, or equipment.

8. Accessories and Options: Heavy-duty connectors often offer a range of accessories, such as hoods, covers, strain relief, cable glands, or protective caps, to enhance functionality, strain relief, and environmental protection.

These components work together to create a reliable and robust electrical connection suitable for challenging industrial applications where durability, reliability, and resistance to harsh conditions are essential. The specific configuration and features of heavy-duty connectors can vary based on the application requirements and standards.